MENU

Categories

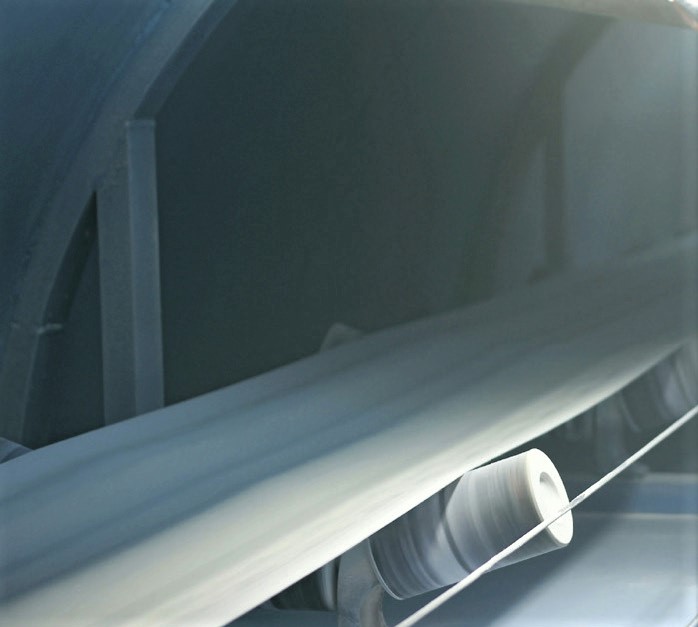

Working conditions in sugar factories are very demanding and every device must meet high safety standards and, at the same time, meet customer expectations in terms of quality and durability. The conveyor belts supplied by Textilco to sugar industry are made of lightweight materials that meet the highest requirements for working loads and breaking strength. Special textiles used for their manufacture guarantee that belt edges remain flat and the belts perform well in both flat and trough (gutter) conveyors. It is possible to protect belt edges using the Seal-Tex method, thanks to which we eliminate possible impurities. The belts we deliver can be used in contact with food. They comply with international EU, FDA and ATEX standards. Belts designed for sugar industry have been developed to optimise production line’s safety and efficiency.

PRODUCT MIX

QUALITY STANDARDS

Conveyor belts are basic products used in meat industry. With this in mind, we are constantly expanding our product portfolio and improving the parameters and properties of existing products. This is conducive to streamlining standard production processes and improving their efficiency. We offer comprehensive services in the field of belting dedicated to meat industry. The guarantee of choosing the right product for every stage of meat processing is possible with high quality coatings.

PVC BELTS 65 SHA

PU POLYURETHANE BELTS

NITRYL AND BUTYL BELTS

MODULAR BELTS

The basic requirement in the production of biscuits is that dough does not stick to the conveyor or process belt, except for one application - forming. For this reason, we recommend using polyurethane coated tapes (PU tapes). In order to easily detect product contamination or dough ribbon break, we have expanded our range of belts with blue belts, and we have reduced bacterial growth on the belts by developing a series of antibacterial belts. Our range of conveyor belts for bread industry is supplemented with modular belts which are successfully used in such applications as separation, loading and unloading the oven, cooling lines.

ADVANTAGES

aDDITIONAL PRODUCTS

Strength, efficiency, safety, hygiene - these aspects are considered when selecting conveyor belts for dairy industry. Each production stage requires a different type of conveyor belt. Whether it comes to portioning, packaging or thermal treatment, you will find the right product in our array of products.

PU POLYURETHANE BELTS

WHITE AND BLUE PVC BELTS

MODULAR BELTS

BELTS FOR WEIGHER PACKERS

POLYESTER GAUZE BELTS

TOOTHED BELTS

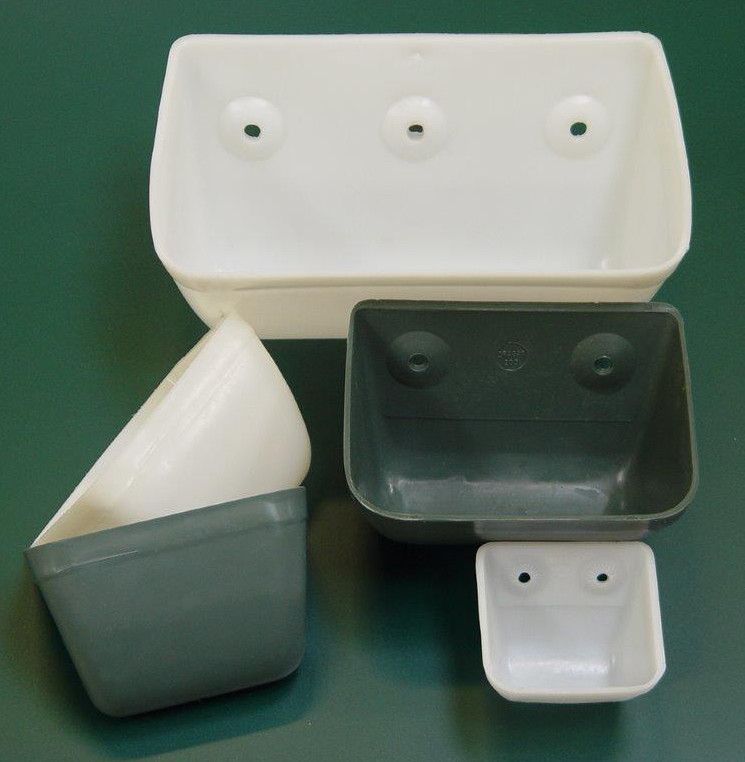

ACCESSORIES

ZALETY TAŚM PRZENOŚNIKOWYCH I PROCESOWYCH DO PRZEMYSŁU SPOŻYWCZEGO

Synthetic belts with additional accessories are the basic products used in fruit and vegetable industry.

PVC BELTS

WHITE AND BLUE PVC BELTS

PU BELTS - POLYURETHANE

POLYESTER GAUZES

ACCESSORIES

ZALETY TAŚM PRZENOŚNIKOWYCH I PROCESOWYCH DO PRZEMYSŁU SPOŻYWCZEGO

Are you interested in our offer? Contact us!