MENU

Categories

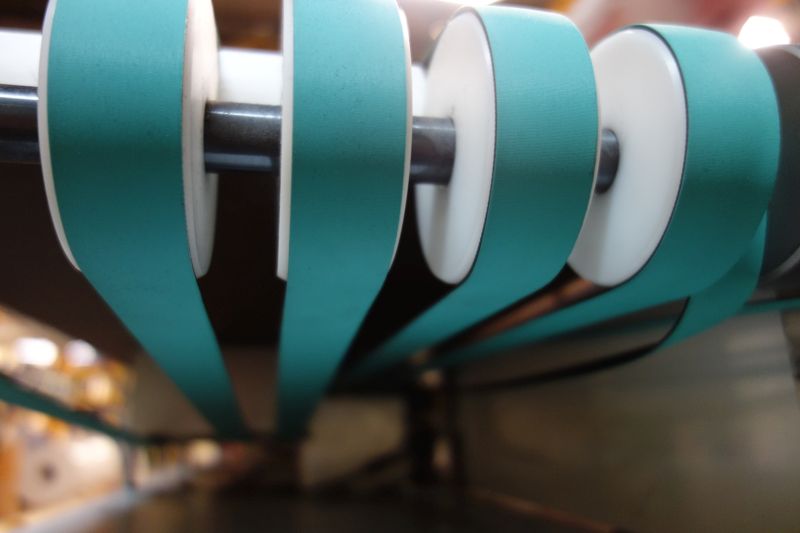

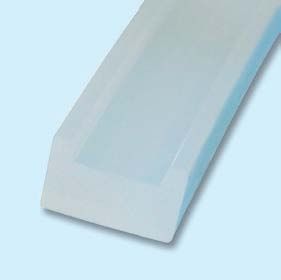

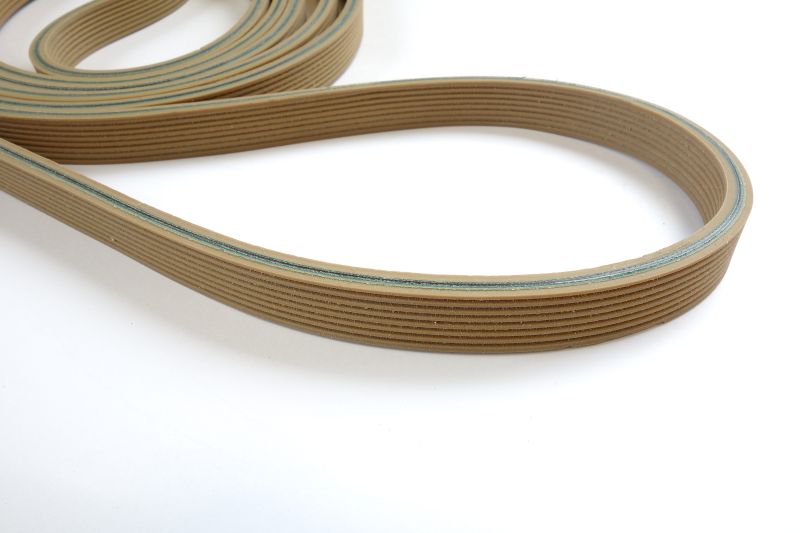

Flat driving belts have multiple industrial applications, from power transmission to sorting mail. We supply classic belts with polyamide (nylon) core, as well as modern solutions with internal thermoplastic insert. Depending on the construction of the belt and the coatings applied, we obtain a wide range of products that will meet your requirements.

properties

applications

types

accessories

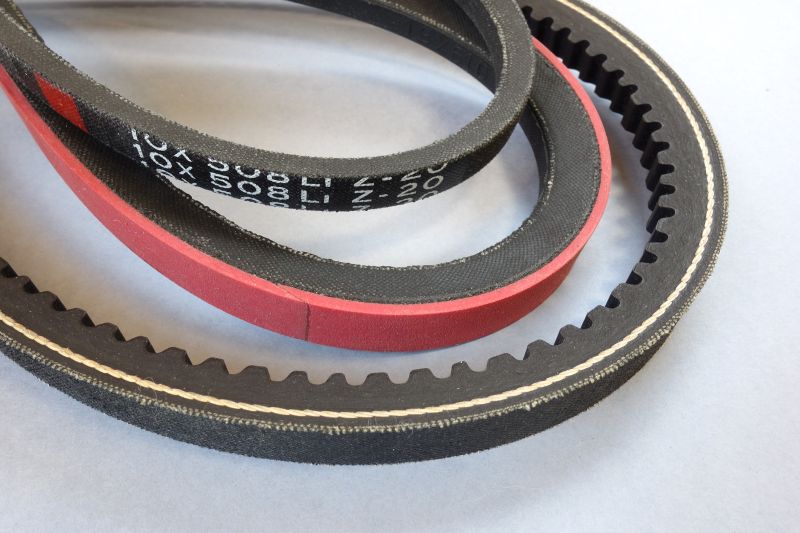

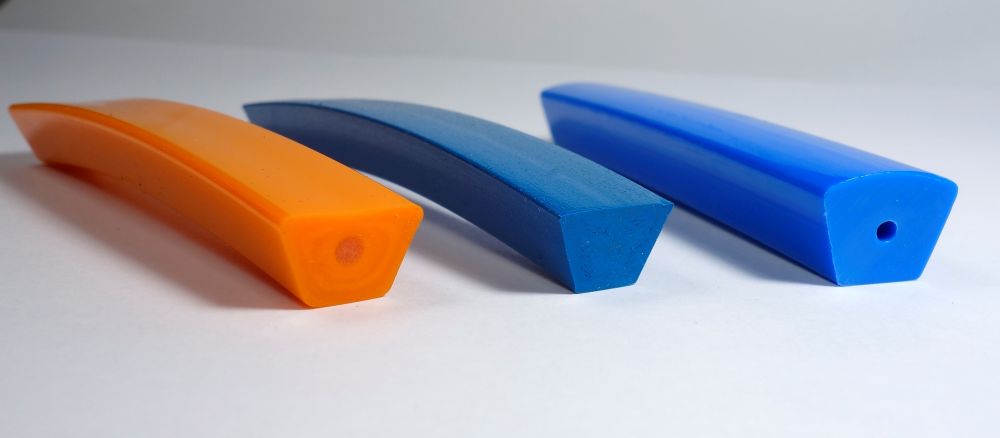

The V-belts we supply come in handy in almost every industry. Classic belts are made of a rubber core, polyester strand, rubber coating over the strand, and a textile coating.

High performance wedge belts are made of a polychloroprene core, a wrapped polyester strand, and belt superstructure.

properties

applications

types

accessories

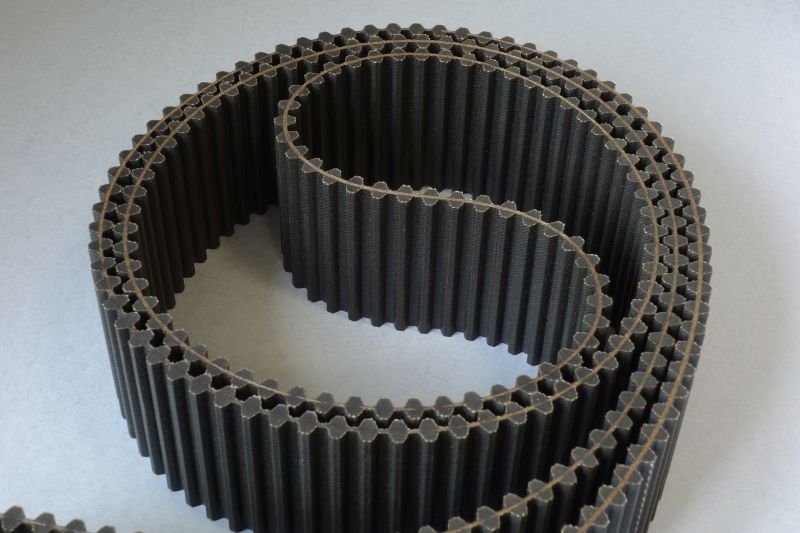

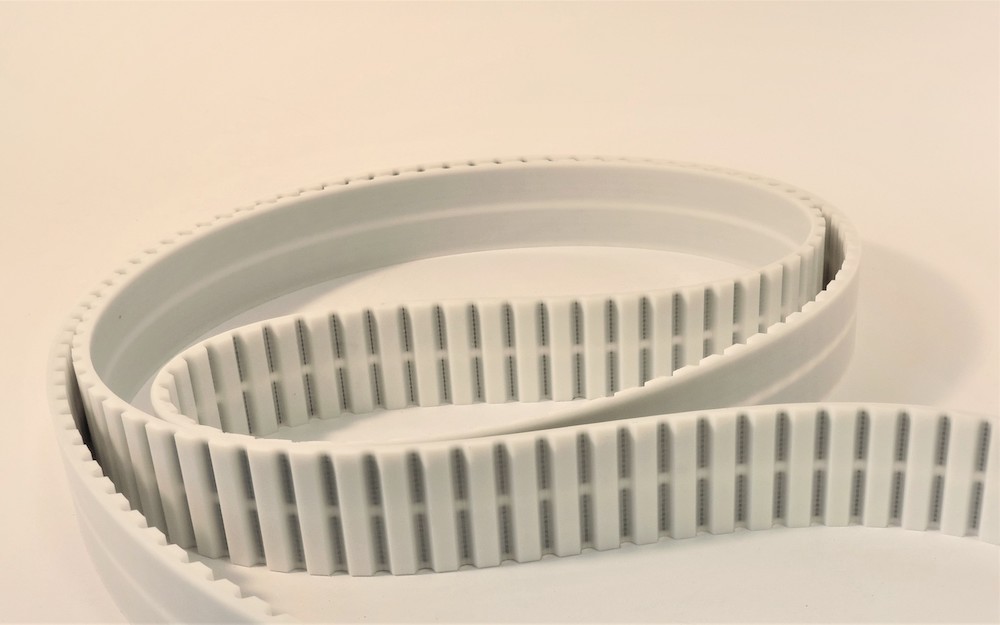

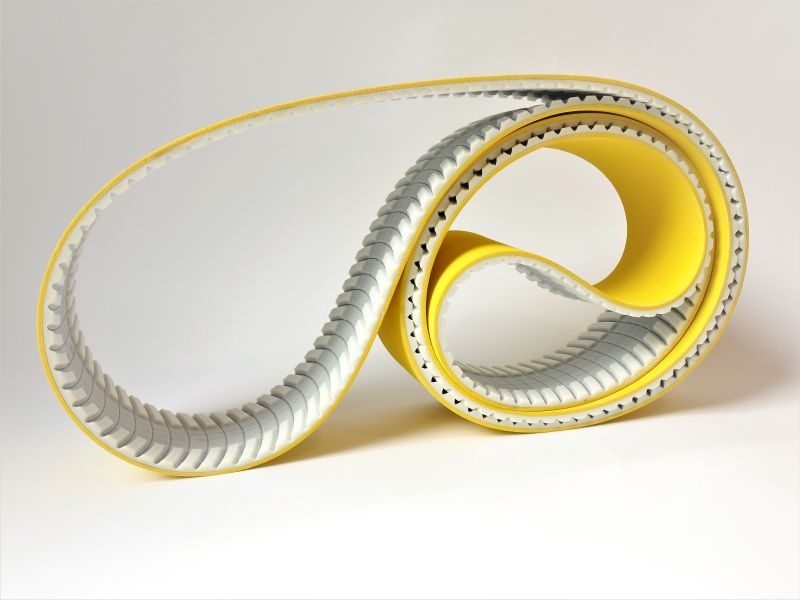

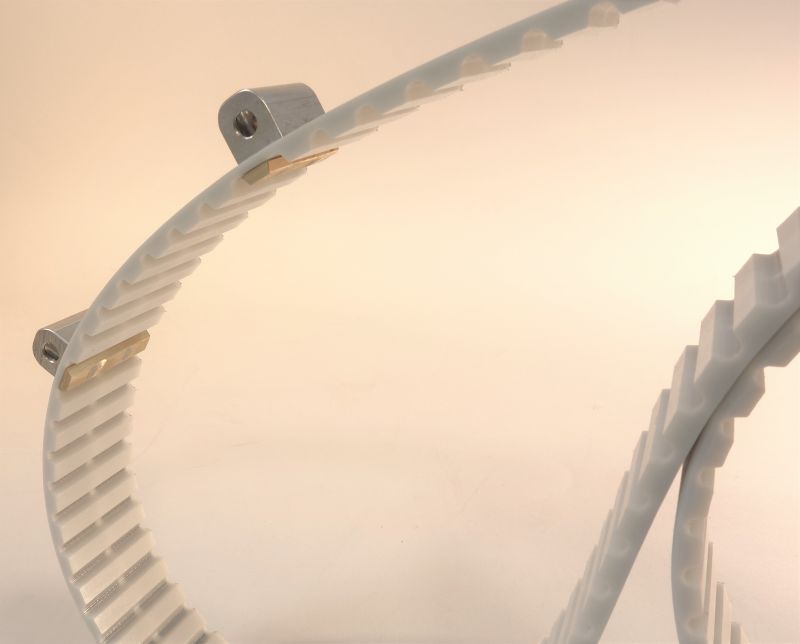

Timing belts are standard solutions for all types of synchronous transport, positioning and power transmission. Different pitch diameters, tooth shapes, different dimensions, coating materials and types of reinforcement enable their use in various applications. Special mechanical and chemical properties are conducive to high machine performance and high precision. Our product range includes polyurethane and rubber toothed belts.

properties

applications

types

accessories

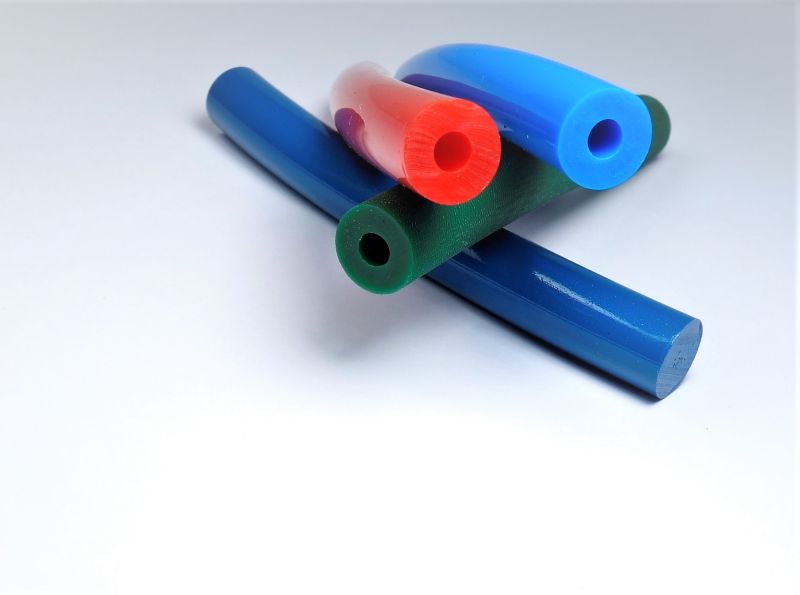

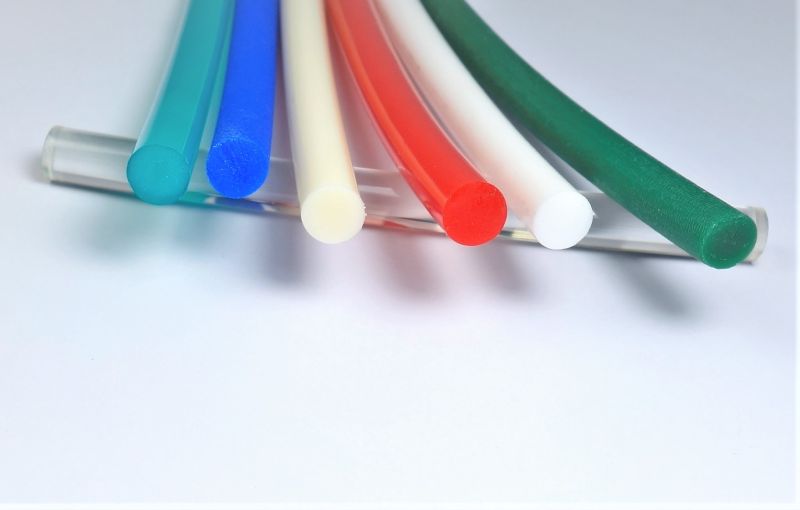

We deal in a wide range of round and V-belts made of thermoplastic polyurethane and polyester. The V-belts and round belts we supply are applied in almost every branch of industry. They are used both to drive machines and transport products, also in food industry. A wide range of belts with various parameters enables customers to select the right product to satisfy their needs.

properties

applications

types

accessories

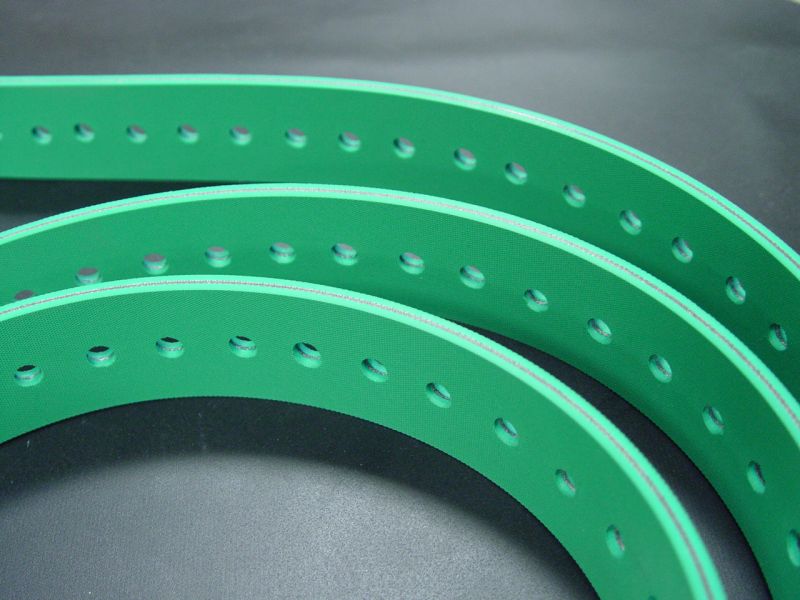

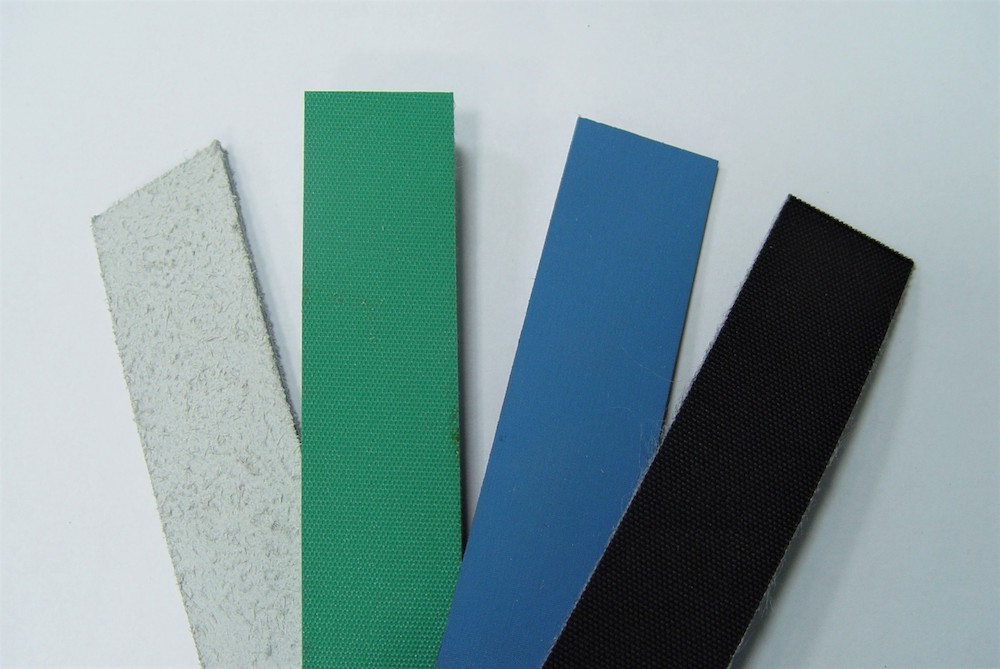

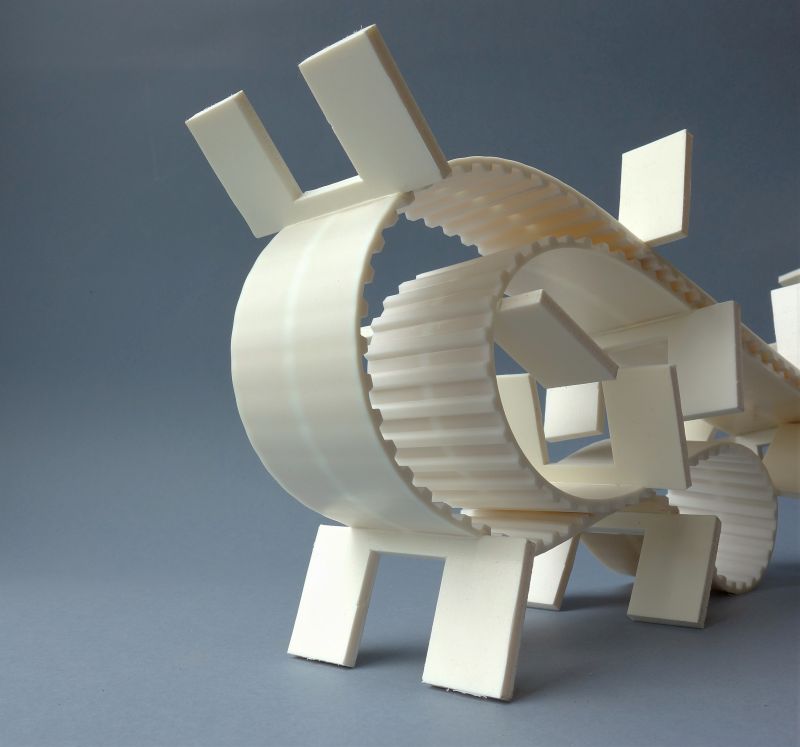

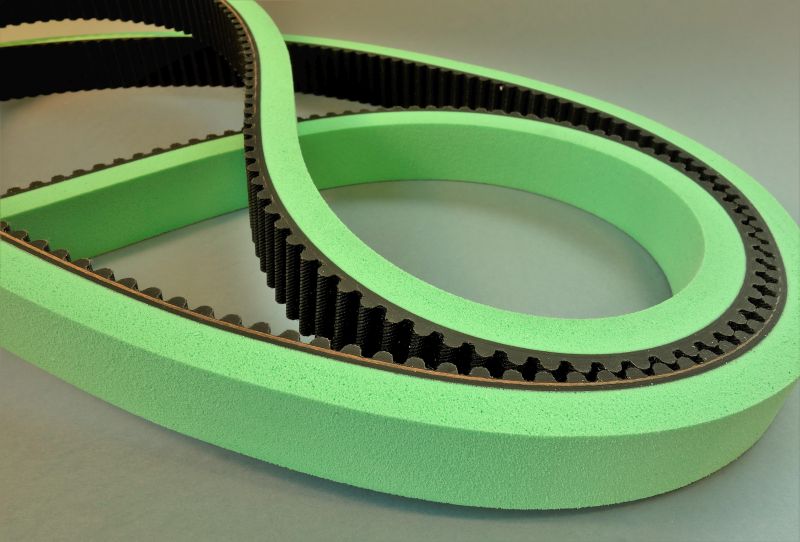

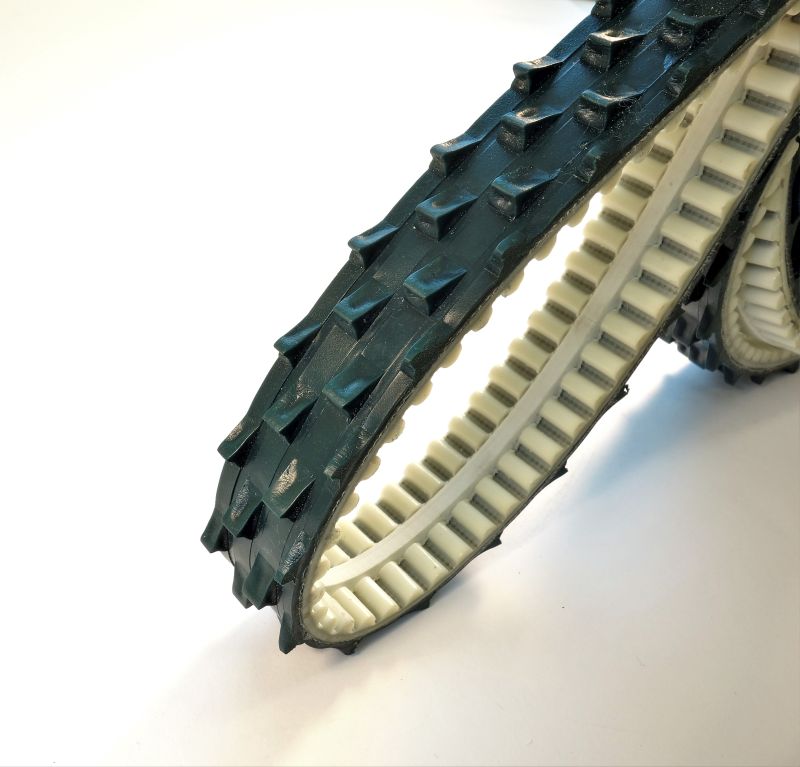

Not infrequently standard belts do not perform well in specific production processes and that is why we offer a wide range of special belts designed for specific applications.

The base of the belt may be

the top side can be

properties

applications

accessories

Are you interested in our offer? Contact us!