MENU

Categories

We apply the following joining methods:

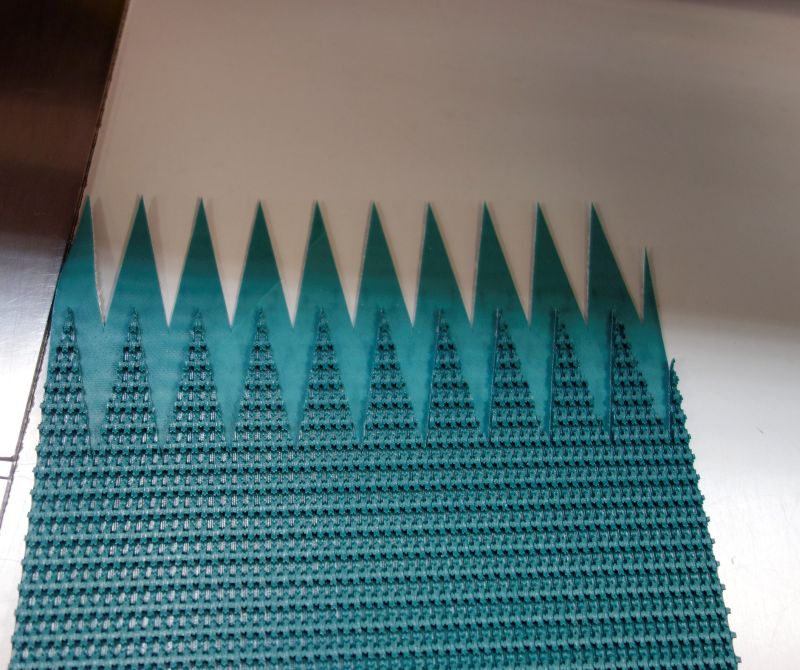

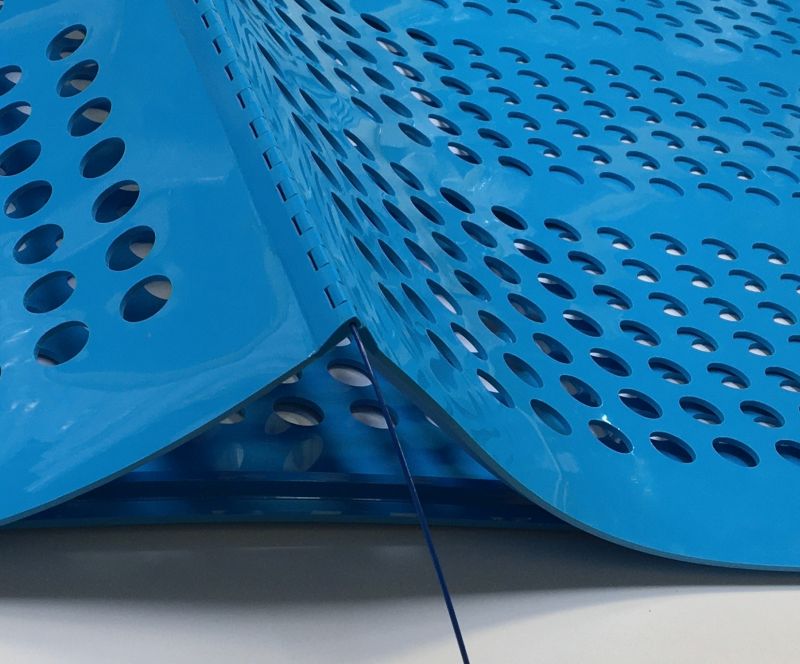

Endless (i.e. joined into a loop)

- single zig-zag teeth

- single Fast-Con teeth

- double teeth

- stepped lap

- ground lap

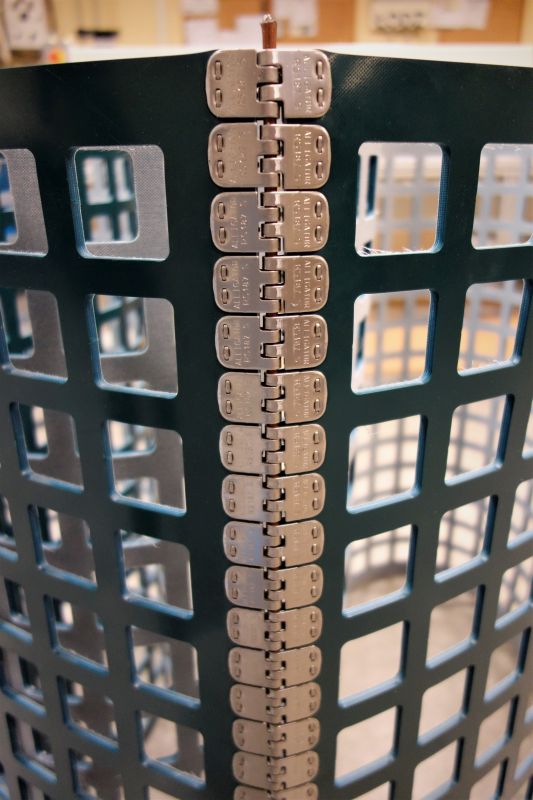

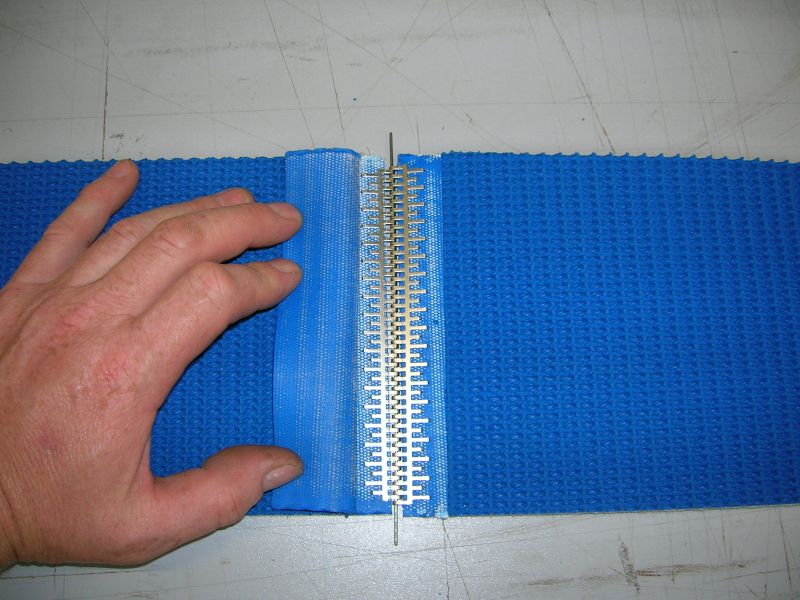

Mechanical (i.e. fastened)

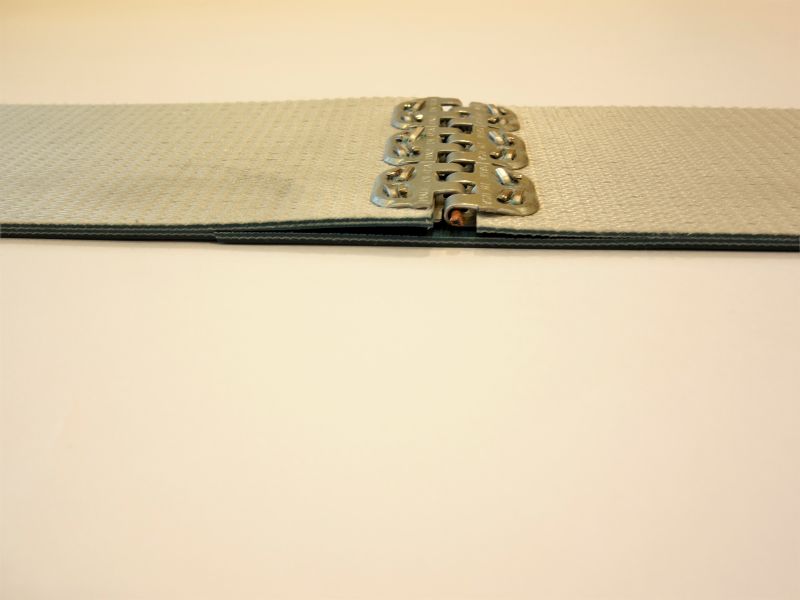

- flat fastener

- a wire fastener

- modular fastener

- plastic fastener

Fastening is recommended when:

- installation of endless belt is not possible

- joining of the belt on the conveyor is not possible, e.g. due to its design

- there is a belt failure, quick repair is required

- the belt is frequently replaced and it is difficult and time-consuming to disassemble the conveyor

Fastening is possible:

- for all types of belts

- for all industry sectors

- in various versions: metal or plastic

We also do fastener coatings to minimise the loss of transported bulk materials and contamination due to the product flowing through the fastener.

Metal fasteners for all types of belts:

- belt thickness from 0.5 to 17 mm

- belt width: from 10 to 6000 mm

- various types of steel: galvanised, acid resistant and other

- types: A, G, Alligator

Plastic fasteners for all types of belts:

- wherever a metal fastener cannot be used, e.g. due to a metal detector

- belt thickness from 1 to 10 mm

- belt width: from 50 to 2200 mm

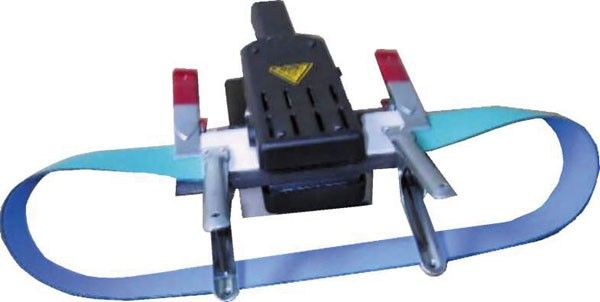

In our offer you can find professional conveyor belt welder, which ensure high quality, efficiency, speed and precision of performance.

advantages

BENEFITS OF USING THE WELDING MACHINE

We supply devices for welding V-belts and round belts. A handy suitcase contains:

- welding machine

- clamp

- 90'and 45' cutters

- penknife

- weld cleaning pincers

advantages

applications

Are you interested in our offer? Contact us!