MENU

Categories

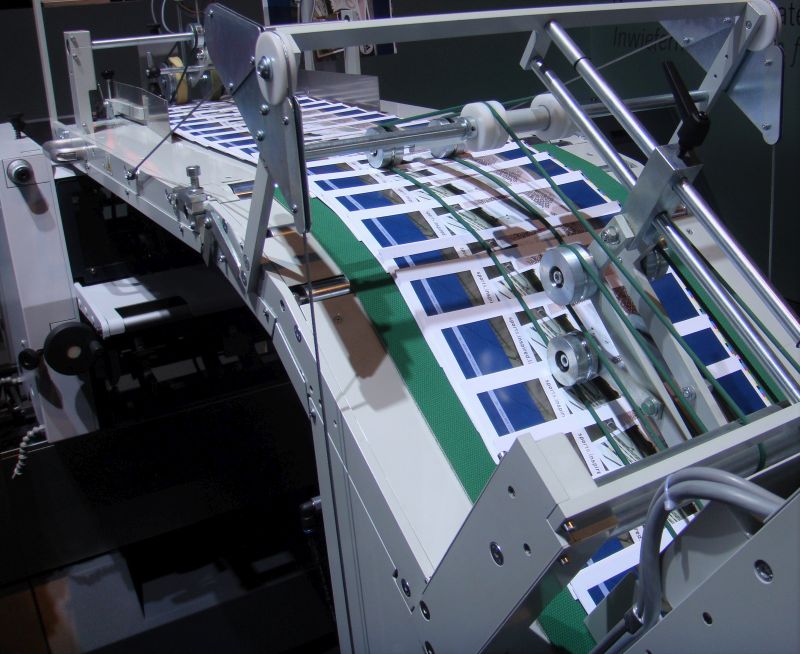

By equipping folding and gluing machines with Textilco belts, you can achieve perfect and precise cutting of cardboard sheets.

OUR PRODUCT RANGE INCLUDES:

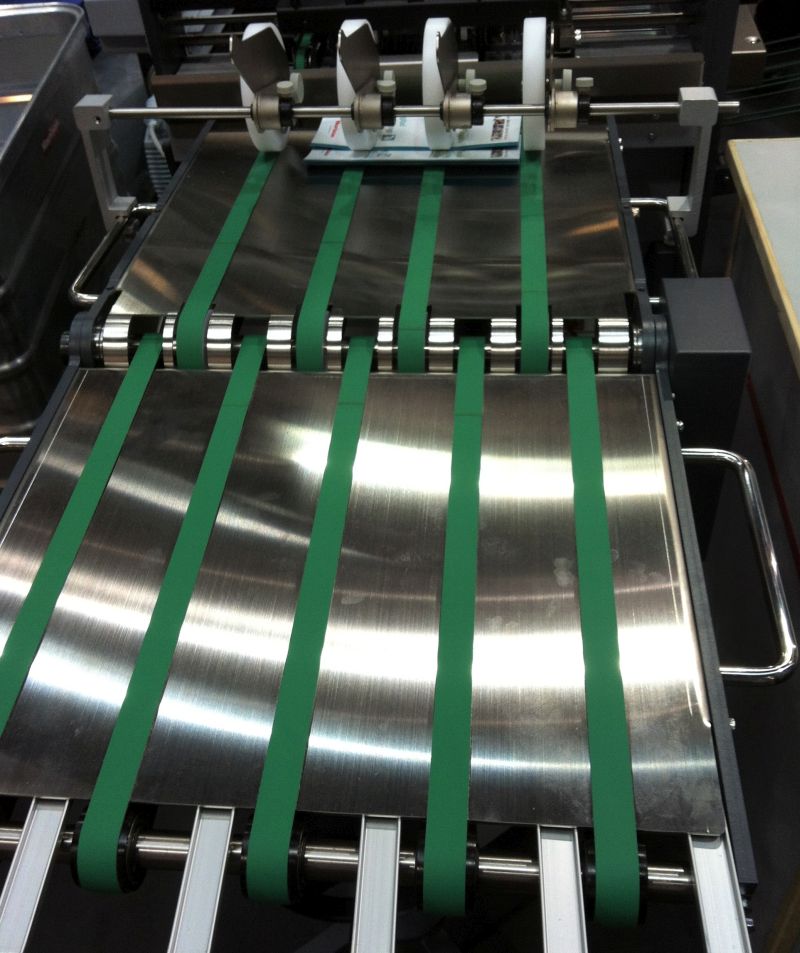

FEEDING BELTS

TRANSFER BELTS

Tube production utilises belts of different thicknesses depending on the tube’s parameters. Characteristically, these belts operate under the impact of high forces. The right choice of coating and its colour guarantees product cleanliness

These belts can operate:

WE SUPPLY THE FOLLOWING BELTS:

In order to select the right belt, please complete the questionnaire for the selection of belts for tube winders.

HEAVY DUTY BELTS - RELIABLE AND PROPER POWER TRANSMISSION

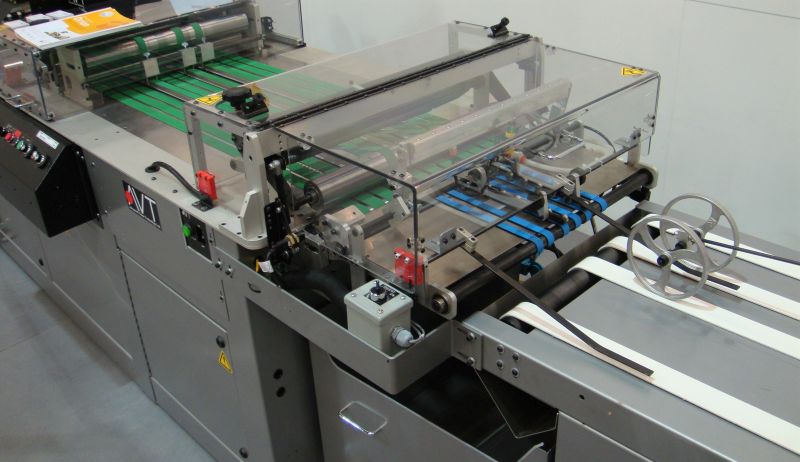

MACHINE BELTS - PAPER SHEETS TRANSFER

CONVEYOR BELTS - TRANSPORT OF PAPER SHEETS AND REAMS IN THE CONVERTING PROCESS

ENGINEERING BELTS - TAILOR-MADE SOLUTIONS

TEXTILCO provides ideal solutions for printing industry, i.e. highly effective machine and transport belts. All of our belts have anti-static properties and ensure proper paper handling. Their excellent performance consists of such elements as: uniform feeding, accurate positioning of paper sheets with no ink stains and no slipping in the course of paper transport. Textilco’s flat belts have extensive post-printing applications. No matter how demanding an application is, we provide a perfect solution. High-grip elastomer coated belts perform best when the printed material is to be transported and aligned after passing through various converting steps, such as feeding, laminating, cutting, addressing, packaging, punching, etc. Belts with lower friction coefficients are used at the folding, storage and shaking stages, when a slight slip is required.

ADVANTAGES OF FLAT BELTS:

No photos

Are you interested in our offer? Contact us!